Functional control charts for multivariate quality characteristics

In this vignette we show how to use the funcharts

package to apply the methods proposed in Colosimo and Pacella et

al. (2010) to build control charts for monitoring a multivariate

functional quality characteristic. Let us show how the

funcharts package works through an example with the dataset

air.

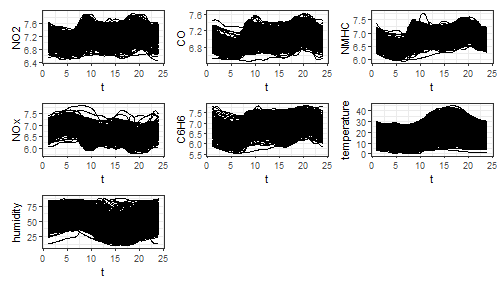

First of all, starting from the discrete data, let us build the

multivariate functional data objects of class mfd, see

vignette("mfd").

library(funcharts)

data("air")

mfdobj <- get_mfd_list(air, grid = 1:24)

nobs <- dim(mfdobj$coefs)[2]

nobs

#> [1] 355

plot_mfd(mfdobj)

In order to perform the statistical process monitoring analysis, we divide the data set into a phase I and a phase II dataset.

rows1 <- 1:300

rows2 <- 301:355

mfdobj1 <- mfdobj[rows1]

mfdobj2 <- mfdobj[rows2]Multivariate functional principal component analysis

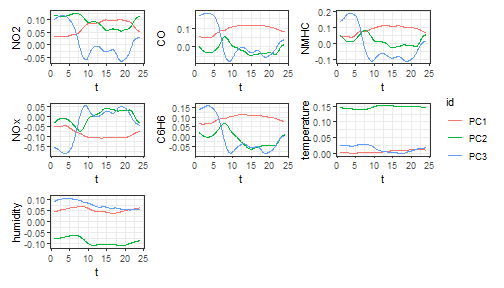

For class mfd we provide a function

pca_mfd, which is a wrapper to pca.fd. It

returns multivariate functional principal component scores summed over

variables (fda::pca.fd returns an array of scores when

providing a multivariate functional data object). Moreover, the

eigenfunctions or multivariate functional principal components given in

harmonics argument are converted to the mfd

class. We also provide a plot function for the eigenfunctions (the

argument harm selects which components to plot).

pca <- pca_mfd(mfdobj1)

plot_pca_mfd(pca, harm = 1:3)

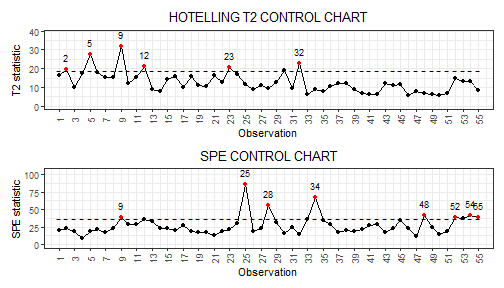

Control charts

The function control_charts_pca provides a data frame

with all the information required to plot the desired control charts on

multivariate functional data, based on the Hotelling’s \(T^2\) and the squared prediction error

statistics (see Colosimo and Pacella (2010), Capezza et al. (2020)).

Among the arguments, you can pass a tuning_data set, that

is not used for model estimation/training, but only to estimate control

chart limits. If this data set is not provided, control chart limits are

calculated on the basis of the training data. The argument

newdata contains the phase II data set of observations of

multivariate functional covariates to be monitored. The function

plot_control_charts returns the plot of the control

charts.

cclist_pca <- control_charts_pca(pca = pca, newdata = mfdobj2)

plot_control_charts(cclist_pca)

Fault detection

Once an out-of-control observation is identified in a control chart, one can obtain the contribution of the functional covariates to the monitoring statistics to understand which variable was possibly responsible of the anomalous observation.

We can get the out of control observations using

which_ooc.

ooc_index <- which_ooc(cclist_pca)

ooc_index

#> $T2

#> n id

#> 1 2 302

#> 2 5 305

#> 3 9 309

#> 4 12 312

#> 5 23 323

#> 6 32 332

#>

#> $spe

#> n id

#> 1 9 309

#> 2 25 325

#> 3 28 328

#> 4 34 334

#> 5 48 348

#> 6 52 352

#> 7 54 354

#> 8 55 355From the control charts it is possible to see some phase II

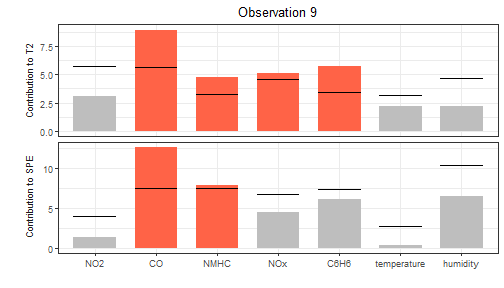

observations out of control. For example, let us consider observation 9.

We can exploit the contribution plots using the function

cont_plot to identify the variables responsible of the

anomaly. The contributions are plotted as bar plots, against upper

control limits estimated empirically on the training data.

cont_plot(cclist_pca, 9) Finally, we can also plot any multivariate functional observation

against a reference data set by using the function

Finally, we can also plot any multivariate functional observation

against a reference data set by using the function

plot_mon:

plot_mon(cclist_pca, fd_train = mfdobj1, fd_test = mfdobj2[9]) This helps to understand which profiles were anomalous. Variables

exceeding contribution plot limits are coloured in red.

This helps to understand which profiles were anomalous. Variables

exceeding contribution plot limits are coloured in red.

References

- Colosimo, BM Pacella, M. (2010) A comparison study of control charts for statistical monitoring of functional data. International Journal of Production Research, 48(6), 1575-1601. https://doi.org/10.1080/00207540802662888

- Capezza C, Lepore A, Menafoglio A, Palumbo B, Vantini S. (2020) Control charts for monitoring ship operating conditions and CO2 emissions based on scalar-on-function regression. Applied Stochastic Models in Business and Industry, 36(3):477–500. https://doi.org/10.1002/asmb.2507